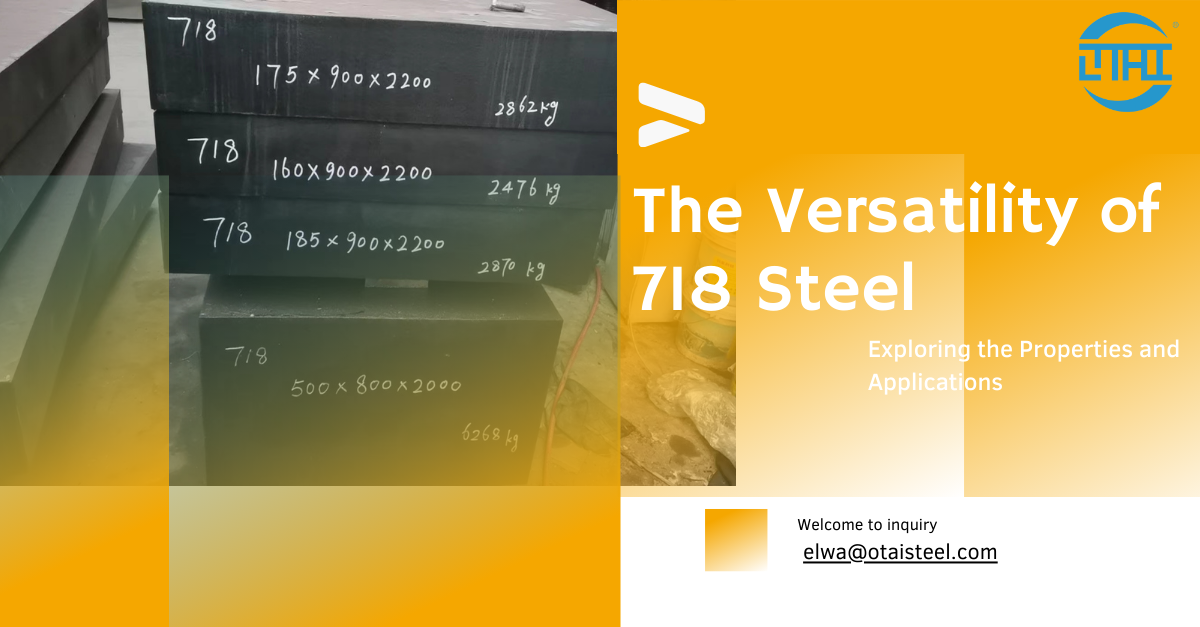

When it comes to advanced materials, 718 steel stands out for its flexibility and widespread use. Its unique blend of properties makes it valuable across multiple industries, from aerospace to automotive and beyond. In this article, we’ll dive into the details of 718 , uncovering its characteristics and varied applications.

The Composition

At its core, 718 steel is a nickel-based alloy known for its strength, corrosion resistance, and ability to withstand high temperatures. Its typical composition includes:

- Nickel (Ni): Provides strength and toughness.

- Chromium (Cr): Enhances resistance to corrosion.

- Iron (Fe): Forms the base of the alloy.

- Molybdenum (Mo): Improves resistance to corrosion.

- Niobium (Nb) and Tantalum (Ta): Increase strength at high temperatures.

- Titanium (Ti): Facilitates hardening for better mechanical properties.

Properties

- Strength and Toughness: It boasts impressive strength, even at elevated temperatures, making it suitable for demanding applications.

- Corrosion Resistance: With its chromium content, this material is highly resistant to corrosion, ensuring longevity in harsh environments.

- Heat Resistance: The alloy maintains its properties at high temperatures, crucial for applications subjected to extreme heat.

- Weldability and Machinability: Despite its strength, it can be easily welded and machined, allowing for efficient fabrication.

Applications

- Aerospace Industry: It is extensively used in aerospace engineering for components like turbine engines and structural parts due to its strength and heat resistance.

- Oil and Gas Exploration: In the oil and gas sector, it is vital for downhole tools and equipment exposed to corrosive environments during drilling and extraction.

- Automotive Sector: Within automotive manufacturing, it contributes to engine parts and exhaust systems, enhancing performance and durability.

- Industrial Applications: In various industries, including chemical processing and power generation, it is valued for its reliability under challenging conditions.

Conclusion

In conclusion, 718 steel offers a versatile solution for complex engineering challenges across multiple industries. Its unique properties make it indispensable for applications where strength, corrosion resistance, and heat resistance are essential. As industries continue to advance, the adaptability of this material ensures its continued relevance in shaping the future of technology and engineering.

FAQs

1. Is it suitable for high-temperature applications?

Yes, it maintains its mechanical properties at elevated temperatures, making it suitable for high-temperature environments such as aerospace and industrial settings.

2. Can 718 be easily welded and machined?

Despite its strength, it is weldable and machinable, allowing for efficient fabrication processes.

3. What industries commonly use 718 steel?

Aerospace, automotive, oil and gas, and various industrial sectors rely on 718 steel for its exceptional properties and performance.

4. How does 718 steel compare to other alloys?

718 steel offers a unique combination of strength, corrosion resistance, and heat resistance compared to other alloys, making it a preferred choice for many applications.